The effects on adhesion performance as a result of replacement of traditional sealants and adhesives by extrusion coatings are described for selected types of packages and packaged goods.

Anti sealing effect in adhesive lamination structures.

The technology of easy open seals and reclosable technology is described.

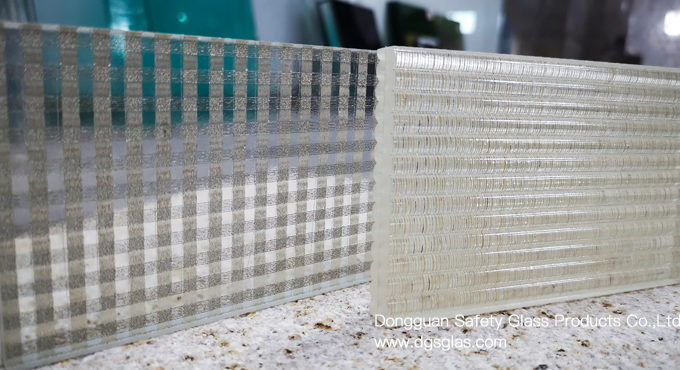

This cured adhesive layer can hinder the sealing properties creating the undesirable phenomenon known as anti seal second generation adhesives which are two part polyurethane adhesives are composed of a polyurethane prepolymer and a polyol both lower in viscosity than a first generation system.

Aspects relating to the foil s surface and coatings barrier will be discussed.

Henkel offers a complete range of products for this application from customized adhesives to ready to use.

The durable user friendly bag is made from a new laminated structure called corrlam vpci barrier laminate which offers unequaled anti corrosion protection.

An outer layer of valeron film provides enhanced puncture abrasion resistance and strength while the cortec vpci 126 ldpe sealant layer provides the anti corrosion protection.

Our adhesives boost the price performance ratio.

Anti overflow adhesive dispenser and use the method for bonding substrate of this anti overflow adhesive dispenser.

Improved film lamination with flexo printing ninety percent of solvent based lamination adhesives for film lamination are currently applied using gravure printing technology.

Henkel laminating adhesives are adapted to meet customer specifications of high setting speed excellent machinability and application without creating a dirty or sticky effect on the roll.